Investment 'Lost Wax' Castings

Precision Investment Castings

Lost Wax Castings, Precision Parts

Pahwa MetalTech is a leading Precision Investment Casting (Lost Wax) manufacturer in India, specializing in high-performance engineering components. We work with non-ferrous alloys such as copper (bronze, brass, OFHC, etc.) and aluminium, as well as ferrous alloys including stainless steels (304, 316, 17-4PH, etc.) and carbon steels.

With advanced vacuum and air melting capabilities, we deliver superior-quality castings for critical applications. Our agile setup and state-of-the-art equipment ensure efficient production for both high-volume orders and small-batch requirements.

We also offer rapid prototyping using consumable 3D-printed PLA patterns—allowing customers to validate designs quickly before moving to full-scale production.

Partner with our expert team today and bring precision, performance, and reliability to your casting requirements

Precision Castings with these Alloys

Over the years, we have developed strong expertise in manufacturing high-quality castings in Copper, Aluminium, and Stainless Steel alloys for demanding engineering applications.

Our Expertise

Our Investment Casting Technologies

Air Melting

We offer Air Melting Investment Castings for non-ferrous - Copper and Aluminum and stainless steel alloys, ensuring reliable quality and performance. Ideal for general engineering and industrial applications, this process is both efficient and cost-effective.

Vacuum Melting

We offer Vacuum Investment Castings for high-performance applications requiring superior purity and precision. Ideal for aerospace and critical engineering components, this process ensures low gas entrapment and excellent metallurgical integrity.

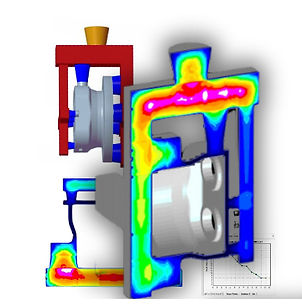

Design & Simulation

At Pahwa MetalTech, we specialize in in-house design of precision tooling for wax investment casting using advanced CAD/CAM systems. We conduct solidification and simulation studies to optimize casting parameters and eliminate defects. This ensures consistent, high-quality castings with excellent dimensional and metallurgical integrity.

Engineering Excellence in Every Step

Beyond casting, we offer end-to-end solutions including critical heat treatment, precision machining, and surface preparation—delivering ready-to-use parts.

Heat Treatment

Our in-house heat treatment furnaces enhance the mechanical properties of cast components, ensuring they meet precise application requirements.

Machining

Leveraging our expert supplier base, we offer fully machined components, delivering ready-to-assemble parts that meet tight dimensional and quality standards.

Surface Treatment

We offer end-to-end solutions to meet the technical requirements of any surface treatments and plating, ensuring components are finished to exact specifications.

Rapid Prototyping

We leverage 3D Printed PLA patterns for Investment Casting, enabling rapid prototyping and the production of extremely low-volume or complex parts where traditional tooling isn't feasible. This approach allows for faster development cycles, reduced costs, and greater design flexibility. It's ideal for validating designs, producing legacy components, or manufacturing intricate geometries without the need for hard tooling.

Industries We Serve

Electrical & Swtichgear

Lost Wax Casting of components for High Voltage Switchgears, Transmission Components, Rigid Bus Bars in High Conductivity Copper and Brass alloys.

Railway & Locomotive

Railways & Metros components like High Tension Line Brass Castings & Spindle Nuts made from Tin Bronze alloys for Wagons Assembly.

Oil Refineries & Gas Installations

Produce a variety of large investment casting components for the oil and gas industry, including loading valve parts, and junction boxes, pumps and valves.

Auto, CV & Electric Vehicles

Thin Walled Castings in Aluminum for Heat Sinks for Battery, Electronic Housing, Control Mechanisms & Manifolds & SS Turbochargers

Medical & Food Processing

High-quality castings with excellent corrosion resistance for the Food, Medical, & Pharmaceutical industries, such as junction and control boxes.

Consumer Appliances

High Strength Aluminum & Stainless steel components for headphones, washing machines, pumps, and metering devices.

Defence & Aerospace

Small-batch manufacturing of components in Copper, Aluminum, and Stainless Steel alloys for applications such as electronic housings & clamps.

Marine, Propellors

Manufacturing Bronze and Brass Castings for Marine applications like Breaching Adaptors and in producing toroidal propellers

Instruments & Sculptures

We collaborate with artist and designers to convert their concepts and ideas into reality via our prototype Investment Casting process.

Get in Touch With Us for Your Investment Casting Requirements

Please fill out the form below and share your requirements with us. Our team will connect with you to provide the most suitable solutions.