Understanding Investment Casting of SS446 Stainless Steel Components, its properties, applications

- Pahwa MetalTech Pvt Ltd

- Oct 11, 2025

- 5 min read

In the world of high-temperature and corrosive industrial environments, material choice determines performance, reliability, and lifespan. Stainless Steel 446 (SS 446) stands out as a high-performance alloy designed to excel where ordinary steels fail. Known for its exceptional oxidation resistance, superior thermal stability, and cost-effectiveness, this alloy has earned its place in demanding sectors such as petrochemical, power generation, and high-temperature processing industries.

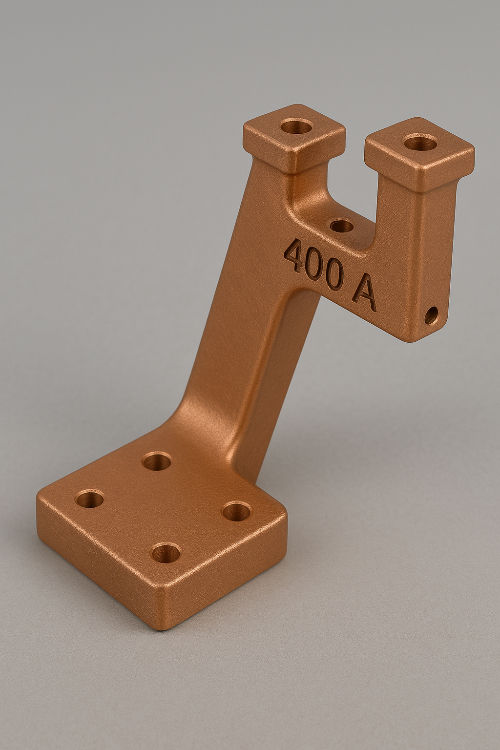

At Pahwa MetalTech Pvt. Ltd., we specialize in precision investment casting of Stainless Steel 446 and other high-performance alloys, ensuring our customers receive components that meet stringent technical and metallurgical requirements.

This article explores the unique characteristics and challenges involved Investment Castings of SS446 Stainless Steels, and how Pahwa MetalTech is the able to overcome these challenges and is a trusted partner for sourcing precision components in this advanced alloy.

What is Stainless Steel 446?

Stainless Steel 446 (UNS S44600, AISI 446) is a ferritic stainless steel — a family known for its magnetic properties, high chromium content, and body-centered cubic (BCC) crystal structure. Unlike austenitic stainless steels (such as 304 or 316), ferritic grades contain little to no nickel, which makes them more cost-stable while maintaining robust resistance to oxidation and corrosion. Check out our article on Lost Wax Casting of Thin Walled SS316 Stainless Steel Components.

Composition Overview

Typical chemical composition of SS 446 includes:

Chromium (Cr): 23–27% – The defining element responsible for outstanding oxidation resistance.

Iron (Fe): Balance (~70–75%) – The matrix metal that stabilizes the ferritic structure.

Carbon (C): ≤ 0.20% – Kept low to enhance corrosion resistance.

Silicon (Si) and Manganese (Mn): ≤ 1.5% each – Improve deoxidation and high-temperature strength.

Trace elements like Phosphorus, Sulfur, and Nitrogen are tightly controlled to ensure ductility and minimize inclusions.

This unique chemistry enables SS 446 to retain its ferritic structure and mechanical integrity up to 1150°C (2100°F) — a temperature range where most other stainless steels lose strength or deform.

Key Features of Stainless Steel 446

Exceptional Corrosion and Oxidation Resistance

The hallmark of SS 446 is its ability to resist oxidation and scaling even at continuous service temperatures up to 1150°C. The high chromium content forms a stable chromium oxide film, protecting the surface from further degradation even under cyclic heating.

High-Temperature Stability

SS446 Stainless Steel maintains strength and dimensional stability in extreme heat. This makes it ideal for Furnaces, catalytic converters, Heat exchanger parts, Burner assemblies, Recuperators and radiator components.

Durability and Longevity

With its combination of mechanical strength, thermal stability, and corrosion resistance, SS446 Stainless Steel offers an extended service life, reducing downtime and replacement costs in high-temperature industrial systems.

Properties of Stainless Steel 446

Mechanical Properties (Typical Values)

Property | Metric | Imperial |

Tensile Strength | 450–620 MPa | 65–90 ksi |

Yield Strength | 280–380 MPa | 40–55 ksi |

Elongation | 20–25% | — |

Hardness (Brinell) | 170–220 HB | — |

SS 446 is not as ductile as austenitic steels, but it compensates with superior high-temperature strength and stability.

Thermal and Physical Properties

Density: 7.6 g/cm³

Melting Point: 1510–1530°C

Thermal Conductivity: 24.2 W/m·K at 20°C

Coefficient of Thermal Expansion: 11.2 × 10⁻⁶ /°C (20–100°C)

Magnetic: Strongly ferromagnetic

Corrosion Resistance

Excellent in oxidizing environments and air at elevated temperatures

Good in nitric acid and sulfurous gas atmospheres

Fair in alkaline conditions

Not recommended for reducing acids or high-chloride marine exposure

Applications of Stainless Steel 446

Given its balance of thermal endurance and corrosion resistance, SS 446 is widely used across high-temperature industries.

Industrial Furnace Components

Radiant tubes and retorts

Heat exchangers

Recuperators and muffles

Burner nozzles and trays

Petrochemical and Power Generation

Superheater and economizer tubes

Boiler components

Gas turbine combustors and ducting systems

Biomass and incineration plant equipment

Automotive and Transportation

Exhaust manifolds

Mufflers and silencers

Catalytic converter housings

Heat shields and protective exhaust components

Chemical and Process Equipment

Reaction vessels

Catalyst support structures

High-temperature reactor internals

Appliance and Consumer Equipment

Commercial oven components

Industrial heating elements and housings

Thermal insulation supports

These applications leverage SS 446’s resistance to scaling, oxidation, and thermal fatigue, ensuring consistent performance under demanding service conditions.

Challenges in Investment Casting of SS446 Stainless Steel

While SS 446 offers exceptional performance in service, its casting process is technically demanding due to the alloy’s high chromium content and ferritic nature.

Key Casting Challenges

High Melting Point: Around 1450–1500°C, requiring precise temperature control to avoid cold shuts and incomplete fills.

Oxidation & Scaling: Chromium promotes oxide formation during melting; maintaining controlled atmosphere is crucial.

Brittleness & Limited Ductility: Ferritic steels are more prone to cracking if not properly cooled or fed during solidification.

Shrinkage & Distortion: Complex geometries need optimized gating, risering, and shrinkage allowances.

Porosity & Gas Entrapment: Requires moisture-free molds and controlled pouring velocity to prevent voids.

Achieving defect-free Stainless Steel 446 castings requires precise control over melting temperature, mold design, and atmospheric conditions — supported by deep process expertise. These are precisely the areas where Pahwa MetalTech Pvt. Ltd. excels.

A leading Indian manufacturer of precision investment castings (Lost Wax Castings), Pahwa MetalTech specializes in stainless steel, copper-based, and aluminium alloys. Driven by innovation, precision, and a strong commitment to quality, the company delivers customized casting solutions for demanding industrial applications across the globe.

With an experienced workforce, state-of-the-art manufacturing facilities, and a profound understanding of metallurgical behavior, Pahwa MetalTech continues to be the preferred partner for high-performance alloy castings.

Care to be Taken During Lost Wax Casting of SS 446

Investment casting (Lost Wax Casting) is ideal for SS 446 due to its ability to produce precise, complex geometries with minimal machining.

Best Practices for SS 446 Casting

Wax Pattern Preparation: Use of good quality wax, Ensure dimensional accuracy and uniform shell thickness to accommodate ferritic shrinkage.

Investment Material Selection: Use high-purity, high-refractory ceramic shells to withstand the alloy’s pouring temperature.

Temperature Management: Maintain precise melting and pouring temperatures (above 1500°C) and uniform preheat of shells.

Controlled Atmosphere: Inert or vacuum environments minimize oxidation and gas pick-up during melting.

Post-Casting Heat Treatment:

Annealing (1050–1150°C) relieves stresses and enhances ductility.

Surface Finishing (grinding, pickling, or machining) ensures superior surface quality.

At Pahwa MetalTech, every step — from pattern design to final machining — is managed under strict process discipline, ensuring castings meet both dimensional and metallurgical integrity standards.

Economic and Performance Advantages

Cost Efficiency

The absence of nickel in ferritic stainless steel 446 makes it more price-stable and economical compared to austenitic grades like 310 or 316, especially during nickel price volatility.

Performance-to-Cost Ratio

SS 446 provides an excellent balance of high-temperature performance and affordability, particularly for long-life furnace and heat-resistant applications.

Sustainability

Ferritic stainless steels are 100% recyclable and have lower embodied energy compared to nickel-rich alloys, aligning with global sustainability goals.

Partner with the Experts in Stainless Steel 446 Casting

If your project demands high-temperature reliability, precision, and performance, Stainless Steel 446 could be the ideal material. And when it comes to casting SS 446 with precision and consistency, Pahwa MetalTech Pvt. Ltd. is your trusted partner.

Contact us today to:

Discuss your design and alloy selection needs.

Explore customized investment casting solutions.

Learn how our expertise in SS 446 and other high-performance alloys can enhance your product reliability and service life.

E-mail us at info@pahwametaltech.co.in or visit our website ww.pahwametaltech.co.in

Comments