Non Sparking Tools & the Fire Triangle – How Ignition Is Prevented in Explosive Industries?

- Pahwa MetalTech Pvt Ltd

- 25 minutes ago

- 3 min read

Fire and explosion risks remain among the most serious safety threats in industries that handle flammable gases, vapors, liquids, and combustible materials. Many ignition incidents still occur during routine maintenance and repair activities. One of the most common but overlooked causes is the improper selection of hand tools.

Understanding the connection between non sparking tools and the fire triangle is essential for controlling these risks.

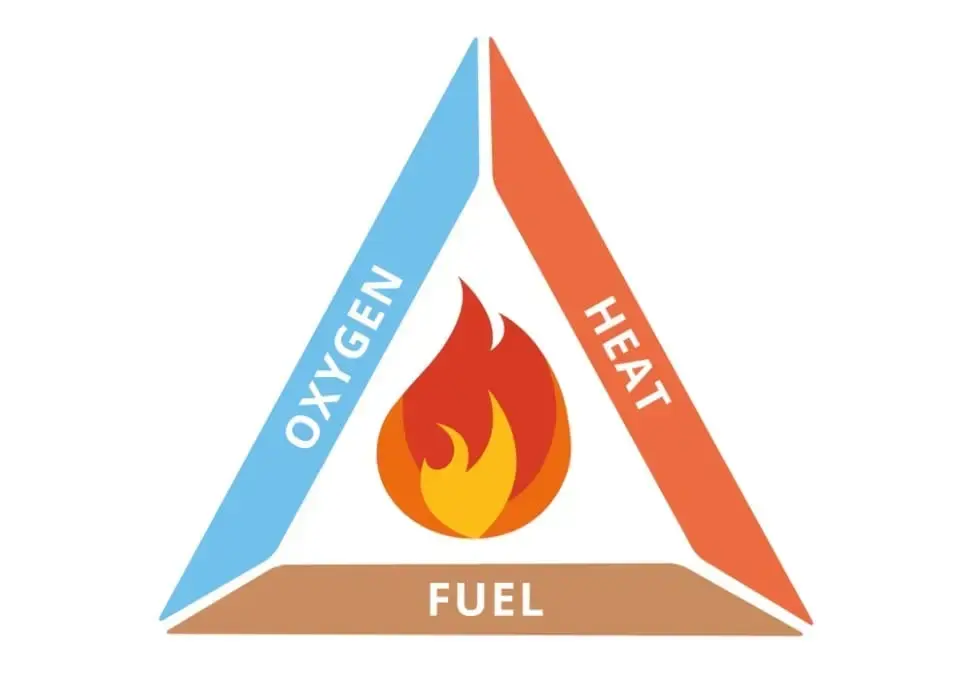

The Fire Triangle - Fundamentals

The fire triangle is a fundamental principle of fire safety. It explains that three elements are required for fire to occur: fuel, oxygen, and an ignition source. Fuel may be present in solid, liquid, or gaseous form, while oxygen is naturally available in air. When a spark or heat source is added, combustion becomes possible.

In industries that manufacture, store, or handle flammable materials such as petrol, diesel, hydrogen, LPG, solvents, and chemical vapors, these substances are essential for operations and cannot be eliminated. Oxygen is also continuously present in most working environments and cannot be removed. As a result, the only practical way to prevent fire and explosion is by controlling and eliminating potential ignition sources.

Since fuel and oxygen cannot be controlled, fire prevention focuses on eliminating ignition sources. Common ignition sources include electrical sparks, static discharge, hot surfaces, welding activity, and mechanical friction.

Steel tools present a major risk in explosive environments. When steel strikes another metal surface, concrete floor, or hardened equipment, it can produce incandescent particles and high-temperature sparks. These sparks carry enough energy to ignite flammable vapors instantly. Even minor tool slips or drops can trigger serious incidents.

In daily operations, spark generation can occur in many ways. A spanner slipping on a tight bolt, a wrench falling from height, or a hammer striking near a pipeline can all create ignition risks. Such incidents often happen during routine work and are difficult to predict or prevent without proper tools.

We have compiled numerous case studies documenting incidents where the use of conventional steel tools generated sparks in flammable and confined environments, leading to fires and explosions. To learn more about these real-world incidents and safety lessons, refer to our detailed article section on related accidents.

How Non-Sparking Tools prevent Ignition?

Non sparking tools are designed specifically to prevent this situation. These tools are manufactured from non-ferrous alloys that do not produce high-temperature oxidizing particles when subjected to impact or friction. Instead of creating sparks, they absorb and dissipate mechanical energy safely.

When non sparking hand tools strike hard surfaces, the material undergoes controlled deformation. Heat is released gradually, and no incandescent particles are formed. This behavior prevents ignition even under high load and repeated use. As a result, the ignition side of the fire triangle is effectively removed.

In modern safety systems, non sparking tools are considered engineering controls. They provide built-in protection that does not depend solely on worker behavior. Unlike procedural rules, which can be ignored or forgotten, properly designed tools offer continuous and reliable safety performance.

Non-Sparking Testing

To determine whether a material is suitable for manufacturing non sparking tools, it must undergo standardized safety testing. One of the most important tests is IS 4595, where the material is evaluated in a controlled flammable environment and deliberate attempts are made to complete the fire triangle through friction and impact. This test verifies whether the material can generate ignition under extreme conditions.

To understand the testing methodology in detail, refer to our article on Decoding IS:4595-1969 (Reaffirmed 2006) Standard for Non Sparking Tools.

For effective fire triangle control, organizations must integrate non sparking tools into their safety management systems. This includes permit-to-work procedures, shutdown maintenance plans, contractor safety programs, and emergency response protocols.

Proper implementation also requires correct tool selection, regular inspection, regular worker training, and secure storage practices. Non sparking tools should always be stored separately from conventional steel tools to prevent accidental misuse in explosive environments.

To learn more about selection, applications, and safety practices, refer to our Ultimate Guide to Non-Sparking Tools for Industrial Safety.

In conclusion, the fire triangle remains the foundation of industrial fire prevention. Where fuel and oxygen are always present, controlling ignition sources is the only effective strategy. Non sparking tools break the fire triangle by preventing mechanical sparks. Their use is essential for protecting personnel, facilities, and operations in explosive environments.

Looking for Non Sparking Tools for your plant? Download our catalog with over 3500+ Non-Sparking Tools - Download

Comments